Framing

ClinchMaster MX4 is ideally suited for a wide variety of framing tasks, from structural framing, partition and curtain walls to solar panel racking and mounting systems.

Video can’t be displayed

This video is not available.

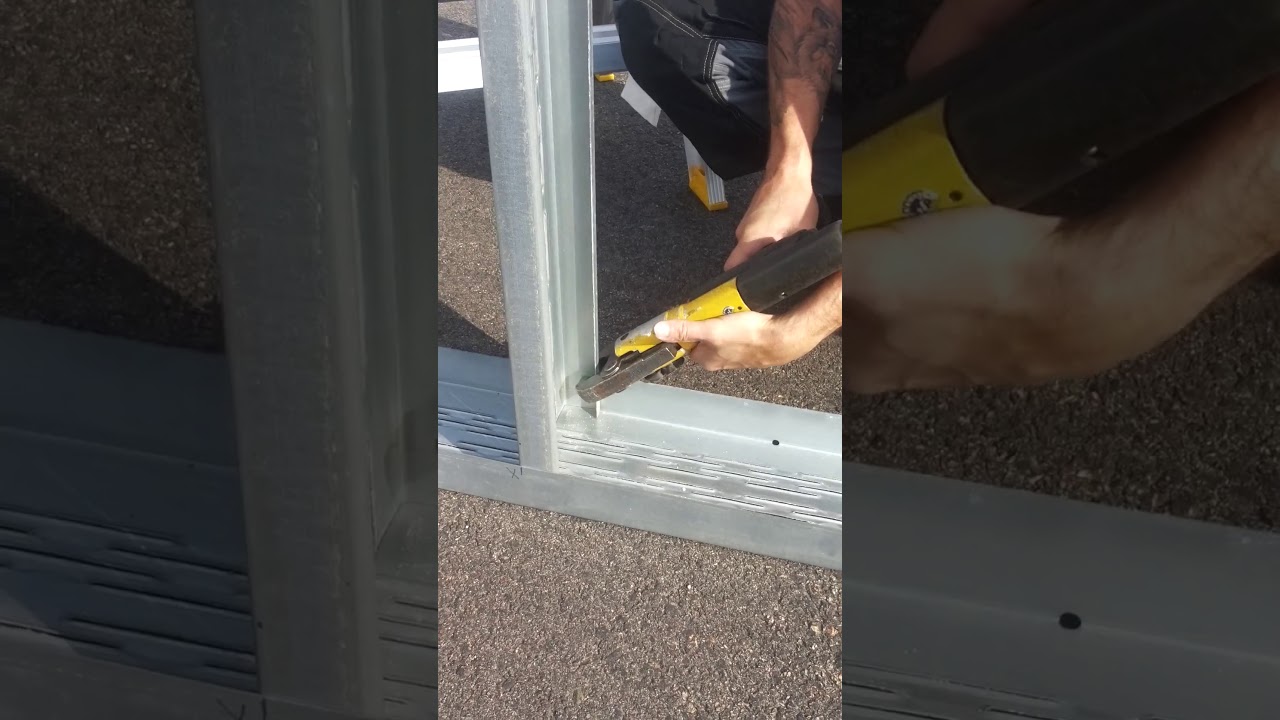

Using vertical studs

This video shows a framing situation where vertical studs are joined to an upper and a lower horizontal track, in an essentially stick building mode.

Instead of using a felt pen mark for positioning, one can punch locating tabs on the tracks in the roll forming process

Note the following advantages

- The operator can join the bottom track without kneeling

- The operator can join the upper track while stretching overhead using just a low step ladder

- The operator can join both side of the frame, staying on one side

- Turning the barrel holding the clinching tong with respect to the grip gives the operator additional comfort

- With the punch on the outside of the frame, the joining zone will be flush without screw heads sticking out, screw heads that may crack the gypsum boards

- Additionally, there are no sharp screw tips inside the frame that otherwise could be a hazard for hand injuries and a risk for damaging cables pulled inside the frame

Using a horizontal jig table

This video shows a framing situation where a horozontal jig table is used as support for the profiles to be joined.

Note the following advantages

- The operator can join both side of the frame from the free upper side

- No need to flip the frame, meaning savings on time and space

- Turning the barrel holding the clinching tong with respect to the grip gives the operator additional comfort

- With the punch on the outside of the frame, the joining zone will be flush without screw heads sticking out, screw heads that may crack the gypsum boards or generating gaps under floor boards

- Additionally, there are no sharp screw tips inside the frame that otherwise could be a hazard for hand injuries

Video can’t be displayed

This video is not available.

Solar panel racking

This photo shows an application from Japan where the ClinchMaster MX4 tool is used for splicing hat shaped purlins.

Note the following advantages

- The operator can work overhead without using a ladder

- No need to push on the tool, reducing stress and strain on arm and shoulder

- Here the tong on the ClinchMaster MX4 tool is fitted with a locating end stop, guaranteeing that the clinch points are at the same distance from the free edge of the overlapping purlins

Cable tray splicing Earth connexions

Cable tray splicing is a recurring task in all PV solar park applications.

The smooth clinch points reduce the risk for cable insulations getting damaged when the cables are pulled.

In order to ensure safe working of any PV solar park installation, safe earth connexions are vitally important.

Using clinching these connections can be made simply, quickly and without added fasteners.

.jpg)